Kimono Pacific

Light, Fusion, Elemental, Curves and Fresh

Livinglass now offers non-laminated etched and patterned glass in addition to our original, beautiful natural materials captured between sheets of real, luminous glass: All Livinglass Materials are Class A fire rated, and water, UV and chemical resistant.

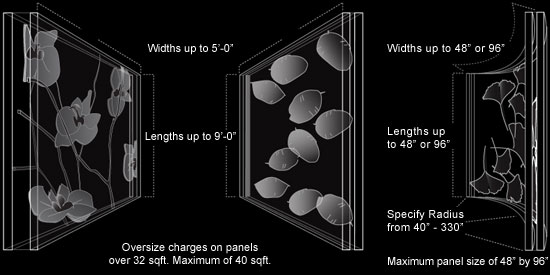

Light and Fusion – Livinglass presents the first 100% environmentally friendly laminated glass. Available with 100% recycled resin and recycled glass, Light panels are thinner, lighter and more budget -friendly. Light starts at ½" thick.

Curves – Expand your design options with our luxurious Curves. Any pattern that can be made in Light can be made in Curves with radii from 40" to 330". Thicknesses are typically ¼" greater than the same material in Light.

Fresh - Modern design sensibilities meet affordability in the first non-laminated line of Livinglass products. Choose from our selection of patterns, up to three patterns per pane of glass, or submit your own. Each pattern can be specified in a selection of luscious finishes

Larger Panels will be quoted on request and will depend on the pattern and/or interlayer.

Technical Information

Livinglass offers non-laminated etched and patterned glass in addition to our original, beautiful natural materials captured between sheets of real, luminous glass: All Livinglass Materials are Class A fire rated, and water, UV and chemical resistant.

Safety

Livinglass is composed of two sheets of glass and a resilient polymer interlayer. Due to the composite action of these materials, Livinglass is an impact resistant safety glass which can be widely specified for both residential and commercial applications. Livinglass laminated glass complies with all Category II and ANSI 97.1 requirements. Livinglass may be specified with tempered glass and through its suppliers, tempered safety glazing products are produced in accordance with the Safety Glazing Certification Council (SGCC) approval for 16 CFR, 1201 Category II impact testing . Livinglass may be specified with tempered glass, and in different thicknesses to satisfy specific engineering requirements. Please note that for life safety applications (safety handrails, flooring, stairs, ceilings) an engineering review is required.

Anti-microbial

Livinglass is antimicrobial and ideally suited to healthcare and sanitary applications. It can be cleaned with heavy duty industrial cleansers or ordinary household products.

Fire Resistance

Livinglass has been tested and rated Class A / Class 1 for fire safety and smoke production. This is the highest standard of fire performance for an interior material, and makes Livinglass suitable for commercial spaces and places of assembly.

Durability

Livinglass is moisture, UV, and chemical resistant. Some Fresh finishes are not recommended for wet environments. See your rep for more details.

Quality

The beauty of Livinglass begins with our unique manufacturing process. First, our interlayer materials are extensively prepared to help protect them against deterioration. Then we laminate them using our proprietary resins and lamination techniques, preserving the 3 dimensional form, color and texture of even the most delicate natural materials and sculptured fabrics. Our clear interlayer provides UV protection while still maintaining the transparency and luminosity of the glass. Unlike most resin and acrylic panels, Livinglass panels are resistant to chemicals, UV light and water. The unique composite action of the materials creates a structurally stable, strong and durable panel that will not sag or deform over time.

Price

Livinglass panels are custom made to order. Pricing depends on the material you choose, the quantity of your order, and any custom details you specify. We will be glad to help you find the material that satisfies your budget and your creativity!

Get a Quote

Livinglass panels are custom made, so you may order panels in virtually any size and shape. (Minimum orders may apply.) To request a quote, email us at info@livinglass.com.

To request a quote please tell us:

- Which material you have chosen

- The number and size of panels .

- The desired thickness – Please note that not all materials can be made in all thicknesses.

- The installation type – Some typical installations are framed, channeled at the top and bottom with vertical edges exposed, and mounted on standoffs through the glass.

- Any custom factors such as tempered or opaque glass, edge polishing, drill holes, etc. Annealed glass is standard. Tempered may be specified for extra strength.

- Drawings such as elevation, installation detail, and design layout are strongly recommended if applicable. For curved or non rectangular panels a digital DXF drawing must be provided.

We will provide a quote promptly, answer your questions, and provide design recommendations to help you detail your Livinglass installation. When you are ready to order, a mockup may be recommended to allow you to appreciate the characteristics of your material at full scale.

Detailing Livinglass

There are several common types of installation for Livinglass:

- Framed – all edges are concealed in a frame.

- Channeled at the top and bottom – the vertical edges are polished to achieve a continuous appearance between multiple panels.

- Mounted on standoffs - we will provide drill holes through the glass per your template.

- Channeled at bottom only – occasionally used as a railing detail. The glass must be tempered and the thickness reviewed by an engineer to ensure that all local safety codes are satisfied.

- Notched and cutouts

- Opacity - for installations where privacy is needed, specify “Mist" for slight opacity or “Cloud" for full privacy